MOBILE CRANE SAFETY

Mobile cranes are used in various industries for maintenance and construction related projects. Whether you work for a construction company or host employer, it is important to understand the basic requirements. This blog will discuss several important operating requirements outlined in OSHA 1926, Subpart CC, Cranes and Derricks in Construction.

Mobile cranes are used in various industries for maintenance and construction related projects. Whether you work for a construction company or host employer, it is important to understand the basic requirements. This blog will discuss several important operating requirements outlined in OSHA 1926, Subpart CC, Cranes and Derricks in Construction.

Ground Conditions

Ground conditions can negatively affect a mobile crane’s capacity and stability resulting in collapse, employee injuries, and property damage. The ground must be firm, drained, and graded. Supporting materials such as blocks, mats, or cribbing must be used in certain situations to ensure stability.

The OSHA standard places the responsibility for ensuring adequate ground conditions with the “controlling entity” at the site. This entity can be the general contractor, construction manager, or other legal entity with overall responsibility for the project’s planning, quality, and completion. The controlling entity must also inform the mobile crane user and operator of hazards beneath the equipment including voids, tanks, and utilities.

Power Lines

Electrocutions can be caused by a mobile crane, load, or load line contacting a power line. The OSHA standard contains specific procedures that employers must follow when operating mobile cranes near power lines. Prior to operating a crane on a work site, the employer must evaluate whether power lines are present in the work area and whether crane operations will come within 20 feet of a power line. If operations will not come within 20 feet during the project, no further precautions are required. If the initial plan for the crane’s use changes, the work zone must be reevaluated.

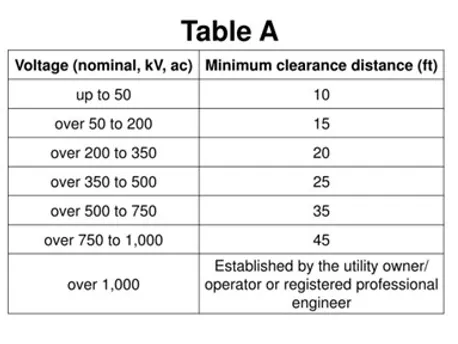

The standard also provides an alternate requirement if the lines voltage is known. Line voltage is determined by contacting the utility provider. Once the lines voltage is determined, the minimum clearance distance in OSHA 1926.1408, Table A can be used:

Should any part of the mobile crane, load, or load line come closer to the power line than the minimum clearance distance (either 20 feet or Table A clearance) the line must be de-energized and grounded, or specific steps must be identified and implemented to maintain the required minimum clearance distance. Required steps include conducting a pre-planning meeting, using non-conductive tag lines, erecting and maintaining an elevated warning line, barricade, or line of signs with flags or similar high-visibility markings at the minimum clearance distances. In addition, at least one of the following measures must be implemented: use of a dedicated spotter, use of a proximity alarm, use of a range control warning device, use of a device that automatically limits the crane’s range of movement, or use of an insulating link or device installed between the end of the load line and the load.

Rated Capacity Compliance

Mobile cranes can collapse when their rated capacity is exceeded. The term rated capacity is defined by the OSHA standard as the maximum working load permitted by the manufacturer under specified working conditions. These working conditions typically include a specific combination of factors such as equipment configuration, radii, boom length and other use parameters. The weight of the load must be determined prior to the lift and the crane must never be operated in excess of its rated capacity.

Conclusion

Mobile crane operations can negatively affect workers’ safety and result in property damage and regulatory exposure. This blog highlighted several, but not all, of OSHA’s requirements for employers. The information within this article, as well as additional crane requirements, can be found in OSHA 1926 Subpart CC, Cranes and Derricks in Construction. Another excellent resource is OSHA’s Small Entity Compliance Guide for the Final Rule for Cranes and Derricks in Construction.

Additional Links:

- Fall Protection Calculations

- Don’t Get Caught In The “Line of Fire”

- Full Course Catalog – Safety Made Simple

Joe Mlynek is a partner and subject matter expert at Safety Made Simple, LLC. He has over 25 years of experience in safety at the corporate level and as a consultant. He is a Certified Safety Professional (CSP) and Occupational Safety and Health Technician (OHST). Joe can be reached at joe.mlynek@safetymadesimple.com