COMBUSTIBLE DUST IN AGRICULTURAL AND PROCESSING FACILITIES

Workers in grain elevators as well as milling and processing facilities are no stranger to combustible dust. Many have experienced the power of these tiny particles first-hand or have seen pictures of the damage caused by dust explosions. If you’ve ever wondered the determining factors that make dust combustible, you’ve come to the right place.

Workers in grain elevators as well as milling and processing facilities are no stranger to combustible dust. Many have experienced the power of these tiny particles first-hand or have seen pictures of the damage caused by dust explosions. If you’ve ever wondered the determining factors that make dust combustible, you’ve come to the right place.

The National Fire Protection Association (NFPA) defines combustible dust as a “combustible particulate solid that presents a fire or deflagration hazard when suspended in air, or some other oxidizing medium, over a range of concentrations, regardless of particle size or shape.” The NFPA further defines combustible dust as “a finely divided organic or metal material, typically 420 microns or smaller.” Combustible dust is capable of causing an explosion when adequate oxygen is present, the dust is suspended in air at the right concentration, a sufficient source of heat is present, and when confined within a structure such as a bin, silo, tank, building, or piece of equipment.

Dust Explosion Chain Reactions

Combustible dust from commodities including wheat, milo, oats, soybeans, rice, hops (malted) and barley can create an explosion under the right conditions. In addition to these materials dust from other agricultural derived materials are also explosive. These materials include wheat and oat flour, cottonseed, sugar, rice starch, potato flour, rye flour, corn meal, corn starch, and semolina. These types of materials are generally handled in facilities that process products for human or animal consumption.

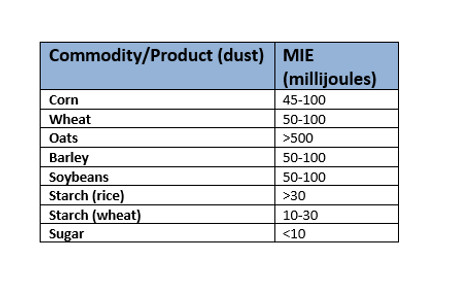

There are three key components that determine the combustibility of dust. The components include the Minimum Ignition Energy (MIE), Minimum Explosive Concentration (MEC), and the Deflagration Index, commonly referred to as the Kst value. The Minimum Ignition Energy (MIE) is the smallest amount of heat or electrical energy that is needed to ignite a dust in air mixture. The MIE is measured in millijoules. The table below indicates the millijoules required to ignite a dust in air mixture based on the commodity or product listed. The lower the MIE the more volatile or explosive the material.

The Minimum Explosive Concentration (MEC) is the minimum concentration of combustible dust suspended in air, measured in mass per unit volume that will support deflagration. Deflagration is defined as combustion that propagates through a gas or across a surface of an explosive at subsonic speeds, driven by the transfer of heat. Put simply, deflagration is the heating of a substance until it burns away rapidly. The MEC is dependent on the size of the particle, the ignition temperature, and the amount of oxygen in the air. In order for a dust explosion to occur, the dust concentration must be between the lower explosive limit and upper explosive limit. Depending on the type of dust and the size of the particles research suggests that the MEC range for grain dust is approximately 50 to 150 grams per cubic meter.

The Deflagration Index (Kst Value) indicates how large an explosion would be by measuring the maximum rate of pressure rise for most favorable dust in air mixtures. The larger the Kst value, the more violent the explosion. For example, the generally accepted Kst value for grain dust is 89 bar-meters per second and the Kst value for corn starch is 202 bar-meters per second. Particle size has a direct relationship to the Kst value in this example. Refined corn starch particles are smaller than grain dust.

Testing dust to determine the Kst value is essential for equipment design. Kst values are used by manufacturers and engineers to validate the design of protection systems including spark detection, deflagration venting, and explosion suppression and explosion containment. Understanding the Kst value is particularly important in processing facilities where commodities are processed or milled. These processes create smaller particle sizes that directly correlate to explosion severity.

Understanding dust combustibility is the first step to preventing dust explosions. With this understanding an organization can identify engineering and administrative controls that can help prevent grain dust explosions and send employees home safely.

References

Occupational Safety and Health Administration (OSHA), Hazard Communication Guidance for Combustible Dusts, 2009.

Jones, Carol. Oklahoma State University, Division of Agricultural Sciences and Natural Resources. Preventing Grain Dust Explosions. Stillwater, OK. Oklahoma State University.

Jarc, Christopher. A. Article Title: Combustible Dust Basics. Retrieved from www.hixson-inc.com.